Why has so little happened with CT detector technology in recent years? The short answer is that the next big leap forward is a giant one. But exciting new technologies are definitely making their way to commercial CT scanners, according to an opening-day talk at the International Society for Computed Tomography (ISCT) 2016 Symposium.

New CT detector technologies are being developed because "today's CT detectors use scintillator materials and they are not perfect," said Dr. Norbert Pelc in a talk presented on behalf of the author, Willi Kalender, PhD, from the University of Erlangen. Kalender couldn't attend this year's meeting due to a broken arm.

Future perfect

What kind of CT detector would be ideal? The next generation of detectors is a tall order by any measure, said Pelc, who is a professor of radiology and bioengineering at Stanford University. Kalender is a professor and chairman of the Institute of Medical Physics at the Friedrich-Alexander-University Erlangen-Nuremberg in Germany.

The ideal CT detector for a scanner would offer 100% absorption efficiency, so that "it would detect all of the x-rays incident on it," Pelc said. "In order to do that, it would also need to have 100% geometric efficiency and not lose any photons because they don't hit any nonsensitive parts of the detector. The signal would come out immediately, so it would have no signal lag or afterglow," he said, referring to the energy that continues to emerge from even the fastest scintillator detectors once switched off.

The ideal detector would also have very high temporal resolution and good energy resolution to provide accurate information about each photon. It would be easy to manufacture, low-cost, and extremely stable, Pelc added.

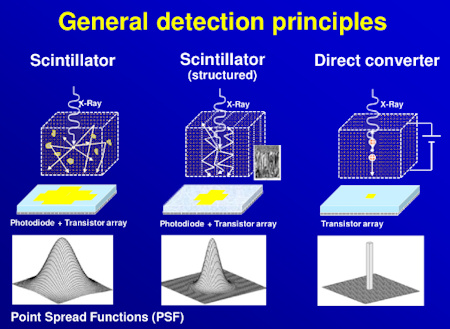

Today's detectors all use scintillators to convert x-rays to light. On the front of today's detector is an array of scintillators, each absorbing x-rays and producing light. The scintillators are isolated from each other with reflector material, so that there is no cross-talk. Typically they are arrayed with 64 detectors in the long direction and 16 channels in the short direction; behind them are the electronics needed to convert the optical signals to electrical signals, amplify them, digitize them, and connect them with the rest of the CT system, Pelc said.

"I've been in the CT field for a long time, and the last commercial detector I helped design had less channels than this module," Pelc said of an example on the screen. "So I think the manufacturers deserve some credit for the extent to which they've been able to integrate and simplify the construction of these detectors so we can have massively multichannel systems."

A typical 64-detector-row scanner consists of 180 channels in the long direction and 64 in the slice direction, all covered by an antiscatter grid. The reflective material is a key weakness of current scintillator-based detectors, reducing geometric efficiency because the x-rays that strike the reflector material don't produce any signal. Even if the reflective material could be removed, geometric efficiency would still be lost on the antiscatter grid, he said.

But detector scintillators are much faster than they used to be, a requirement for today's faster gantry rotation times, Pelc said. New scintillators use ultrafast ceramics or gemstone materials to speed signal transmission. They are "cableless," meaning they are integrated into the electronics without wiring. As a result, electronic noise has been reduced substantially, making the systems more dose-efficient as well.

Direct-conversion detectors

"We are also now starting to see experimental scanners that use direct conversion detector materials" for research use only, Pelc said. The most commonly used materials for these are cadmium telluride (CdTe), cadmium zinc telluride (CdZnTe), and even mercuric iodide (HgI2), although Pelc said he can't think of any large detectors made out of HgI2 just yet.

"These direct conversion materials have been around for decades and used in high-energy physics," he said. They've long sparked interest in the CT community inasmuch as they offer the possibility of photon counting and energy discrimination, which would be "a significant improvement to our CT scanners if we could get them to work reliably and at a reasonable cost."

Direct conversion detectors don't need pixilation, they don't need reflectors, and they don't have dead spaces because of them -- offering the possibility of higher geometric efficiency, Pelc added.

When x-rays come in contact with a scintillator, the light diffuses and spreads, he said. Reflectors are used to isolate the light. But a direct conversion material doesn't generate light, just electrons and poles. The direct conversion detector sends the electrons on a narrow path through the semiconductors in the direction of the charge carriers. The energy doesn't disperse as much as with scintillators, creating a much sharper point-spread function and hence a sharper image.

Thus, while scintillators suffer from light spread, direct detectors have very little charge spread, Pelc said. "For example, for a 1-mm cadmium telluride detector, as the charge diffuses through that 1 mm, the spread of the charge is only 10 to 30 microns, whereas the light from a scintillator would spread much farther," he said.

Higher temporal resolution

The temporal resolution of some detector materials such as CdTe is also quite high, typically well under 100 nanoseconds. "Since the signal comes out so fast, it makes it possible to count individual photons, and, in fact, you can even use them in nuclear medicine for coincidence imaging like for PET," he said.

Today's scintillators are faster than they used to be, but the ones in CT scanners aren't fast enough for photon counting. Scintillators used in CT today exhibit decay times of typically 1 nanosecond or more and an afterglow of at least 50 nanoseconds; both of these qualities prohibit their use in photon counting. That said, some scintillators are fast enough for photon counting, and they're used commonly, Pelc added.

Drawbacks remain

Still, there are potholes in the path forward for cadmium telluride, Pelc said.

"They're available only in small tiles, and you have to have some way to build a large detector out of them; currently we don't have four-way buttable solutions, meaning it's hard to make the detector large in both directions," he said.

| ||||

| Dr. Norbert Pelc from Stanford University. |

"To conclude, there have been advances in traditional photodiode detectors, there is potential for improvement through the use of direct-conversion CT detectors, and we look forward to them in the future being used in clinical CT scanners," Pelc said. Their eventual acceptance in the marketplace "will depend on their performance compared to conventional systems," he added during a later discussion session.

No comments:

Post a Comment